There’s no denying that the EV market has been steadily increasing over the past few years. But there’s also no denying it needs a firm kick up the backside to get where we need it to be, in order to detangle ourselves from Big Oil. The Russian war on Ukraine has kickstarted that kick to our behinds. The current state of the world has shown us that it’s getting less and less smart to rely on fossil fuels. And while ever we do, there’s increased likelihood of continued, devastating conflicts.

So it’s lucky then, that we’ve had a slew of clever people working to iron out some of the initial issues with EVs, and therefore their slow uptake. Let me qualify this statement…while the uptake has been slow in the United States, Australia and Latin America, it’s been bubbling along very nicely throughout Europe, and on fast forward in China. According to the International Council on Clean Transportation, EV sales in Europe grew 143% in 2020 compared to 2019, taking EV purchases to 11% of total new vehicles bought. And by 2035, the expectation is that 100% of new cars sold in Europe will be electric. While in China, the growth of EV sales in 2021 compared to 2020 hit 160%, totaling 3.4 millions vehicles. Conversely, in the US in 2021, EVs made up only 3% of total vehicles sold. And in Australia and Peru it was even worse, with only 1.9% and 1% of new vehicle sales going to EVs, respectively.

One of the major concerns around EVs is so-called “range anxiety”, meaning potential owners are put off by the low distances which can be covered on one battery charge. And with charging infrastructure being slow to take off, this concern is valid for many folks. Things which affect the driving range of an EV are speed, topography, traffic conditions, vehicle weight, ambient temperature and battery materials. There is really only one of those which the driver can control, so there is a need for the assurance of getting from A to B, despite bad traffic and hilly terrain. InsideEVs online mag recently tested 27 EVs to ascertain the driving range. The shortest distance was 51 miles and the longest was 500. Based on their real life driving experience, the average EV will get you about 240 miles.

The real key in improving this performance is the battery technology. This is expected to not only be a determining factor of the price of new vehicles (batteries currently make up about one quarter to one third of the cost of a vehicle), but also outline the possible performance – batteries will soon be as responsible for brand differentiation as unique vehicle body shape. Think of it like the microprocessor of a laptop. So experimentation has been in overdrive. While much of this is happening in China, The US Department of Energy and the Biden Administration are trying to ensure there is plenty of action in the United States too. A recent announcement of nearly $3 Billion being invested to support battery materials refinement, manufacturing facilities, energy storage and recycling facilities to safely manage the end of the battery life. This is in addition to the $7 Billion announced as part of the Bipartisan Infrastructure Bill to support R&D of new battery technology along the whole supply chain of raw material mining, second-life applications for batteries and recycling of battery components to feed back into the supply chain. The private sector, likely bolstered by the Government funding, has been injecting money to the cause too – GM announced investment of $7 Billion which will allow a new battery cell plant, major expansion to their vehicle manufacturing, and importantly, 4,000 new jobs. The company plans to sell only electric passenger vehicles by 2035.

Let’s explore some of the new tech.

Salty Goodness

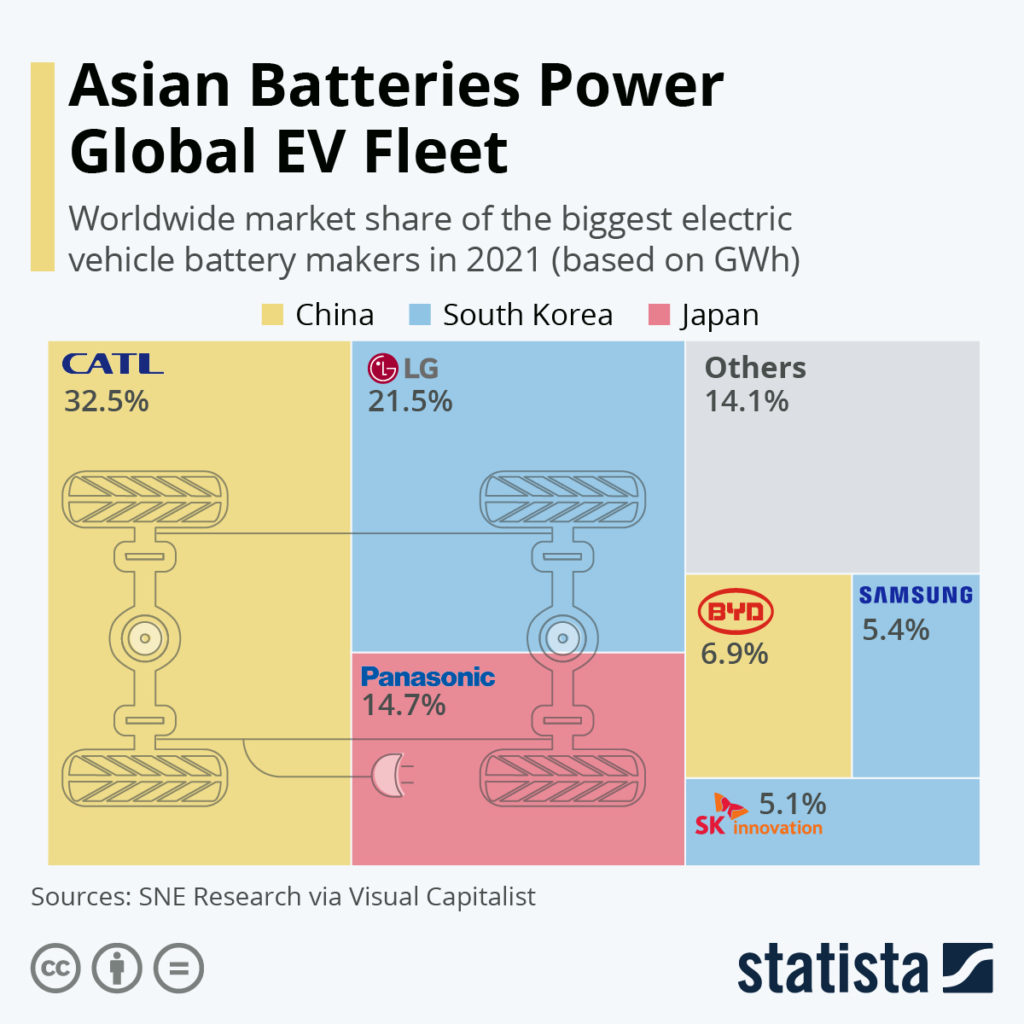

Once upon a time, it was thought that batteries should be made of sodium. Sodium ionizes easily, letting go of one of its electrons. If put inside battery, the ions move back and forth between two plates with opposite charge, thereby generating a current. Although sodium is light, lithium is lighter – and easier to work with – so lithium was soon the gold standard of battery tech. But a company in China, CATL, is trying to give sodium another chance. From 2023 they will be placing sodium cells beside lithium cells in EV battery packs. Not only is sodium less expensive than lithium, it performs better in cold weather and there is less likelihood of global shortages – lithium is a non-renewable resource, located only in very specific places which requires a challenging mining process. Sodium, however, is very easy to come by.

Liquid to Solid

Factorial Energy, a start up based in Woburn, Massachusetts, which just emerged from stealth mode in 2021, are working to upgrade the lithium-ion battery’s liquid electrolyte – which is the substance allowing the electrons to travel between the electrodes. They’re using a polymer material, similar to plastic, instead of the liquid. This solid-state battery has a 50% higher energy density, meaning they are lighter but also offer longer driving range, and they dramatically reduces the risk of fire, sometimes associated with the lower flash point of standard lithium-ion batteries.

Lithium, straight up

Another Woburn based company (but in contrast, is 10 years old), called SES, are building lithium-metal batteries, using a pure lithium electrode, to replace lithium-ion technology. The benefit is once again higher energy density, in fact twice that of lithium-ion batteries, meaning twice the driving range for the same weight of battery. Li-metal batteries aren’t a new idea, but they’ve had the issue of losing integrity after only a few charging cycles. SES claim they’ve worked out the fix to this, and have therefore collected quite a number of high profile car manufacturers as investors, like GM, Honda and Hyundai. The battery manufacturing plant, which will be the largest in the world for Li-metal batteries, is set to open in 2023 in Shanghai, China.

Is Ultium the Ultimate?

GM have also invested in another company, based in South Korea and called LG Chem (the same LG you know from electronics), to come up with a NMCA battery – containing aluminum – called Ultium. These boast the highest nickel and lowest cobalt content of any other battery…and that’s important as cobalt is expensive, rare and often comes with horrendous violations of human rights. The cells can be stacked either vertically or horizontally in the battery pack, and feature a wireless battery management system, to maintain balance within the battery cell groups to obtain optimal performance and longevity (read: driving range).

Bulletproof Polymer

A team at the University of Michigan is using recycled Kevlar, the incredibly strong, heat resistant synthetic fiber used in bulletproof jackets (among a myriad of other things), to form a network of nanofibers which can be used in lithium-ion batteries to overcome the limitations around battery life cycles. Although this doesn’t address “range anxiety”, it’s a potentially important development for overall battery life, which is hugely impactful for reducing the need for recycling/repurposing battery components.

These are just some of the exciting and powerful developments in the EV specific battery world. There’s also excellent work on battery storage and large scale systems being done, which could solve size, durability, reliability and longevity concerns. The future could indeed be electric.