Plastic is the problem that just keeps on giving. It’s literally everywhere (even in the absolute deepest part of the ocean, the Mariana Trench). As we’re all aware, it’s pretty much indestructible and lasts forever. Which was, of course, the reason for great celebration when it was first produced. Fast forward 110 years, and we’re realizing that wasn’t such a great thing after all.

And to make matters worse and the issue even more difficult to deal with, plastic is actually very handy. I’m typing this with plastic keys on a keyboard. Months back, when I took the tram places, I sat on a plastic seat. For lots of good reasons, plastic will likely forever be in our lives. But the plastic which causes the most damage to the environment, based predominantly on the excessive volume, is single use plastic, like packaging and bags. Used for a very short period of time, then discarded to linger somewhere on this planet for millennia.

So there is fast and fervent work being done to come up with plastic packaging alternatives. Preferably biodegradable.

Enter the humble and small prawn, or shrimp. They are a very popular tasty addition to innumerable dishes, enjoyed the world over. And if you’ve ever dealt with the little decapod crustaceans while they’re still wearing their shell, or exoskeleton, you’ll know said shell is actually pretty tough. Insoluble. And flexible. So pretty ideal as a starting point for a plastic bag.

What makes the shell appealing for this use is the element it contains, called ‘chitin’. But by itself, this isn’t going to be wrapped around a sandwich or filled with a beverage.

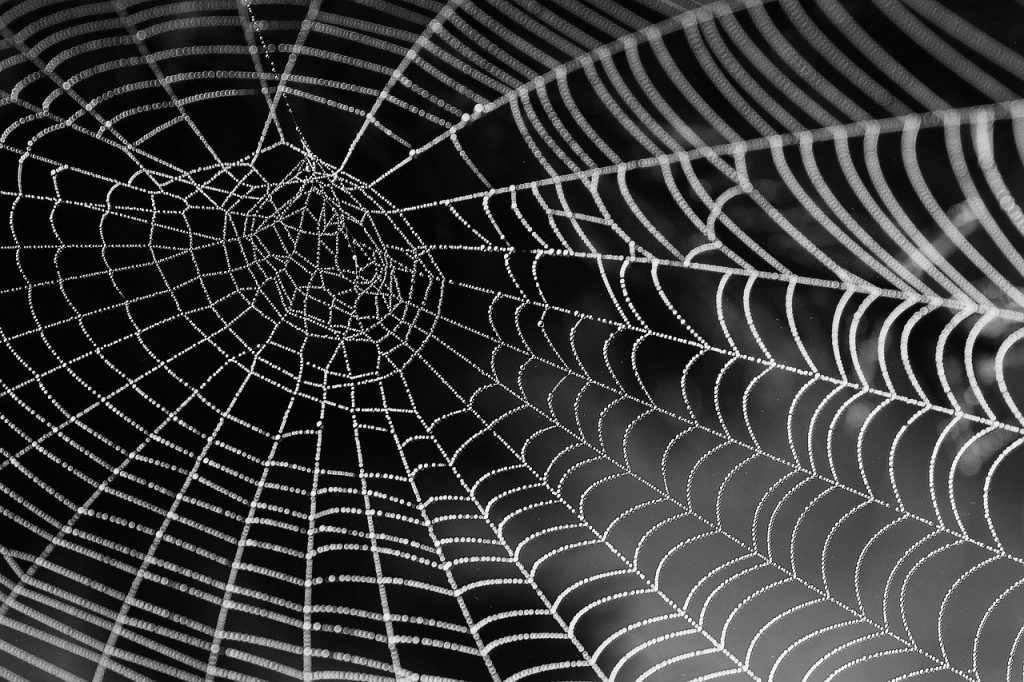

A 17 year old girl in Adelaide, Australia, has been working to come up with a biodegradable plastic for some time. Angelina Arora, like many of her generation, is passionate about finding solutions to preserve our natural environment, and wants to make a positive difference in the world. But she had struggled when it came to making the product insoluble. While eating a prawn meal one night, the thought struck her. So back to the lab she went, looking for a material to partner with the crustacean’s exoskeleton. After quite some testing, she paired the chitosan (which is derived from the chitin) with fibroin, a protein from spider web silk. And it worked!

She produced a clear, flexible, durable, insoluble ‘plastic’, which completely composted in approximately 33 days! Better yet, the nutrients, specifically the nitrogen, contained within the chitin, could be hugely beneficial to soil health as the product decomposes.

But here’s something which makes the story really interesting. In 2014 at the Wyss Institute at Harvard University, this very same thing was discovered and produced: chitosan (that manmade polymer derived from the chitin) combined with silk protein. They even coined the name ‘Shrilk’ for this plastic alternative. However, later that year, they discovered that combining chitosan with wood flour (a waste product of wood processing) produced a less expensive option.

Over in the UK, in 2017, researchers at the University of Nottingham teamed up with Nile University in Egypt, and came up with a similar product. Egypt has a vested interest for two reasons: plastic waste is a huge problem for the country, polluting the waterways and causing health issues for the poorer population; and they have a large amount of prawn shell waste. So this solution seems pretty perfect for them!

But there have been problems – hence we’ve not yet seen this product hit the shelves. It was reported by the University of Melbourne back in 2014 that the issue lies with cost efficiency. Or lack thereof.

So recently, only last month in fact, when young inventor Angelina Arora spoke with media about her creation, it was a great relief to learn that she’s already had discussions with manufacturers and supermarkets to make this product commercially available. She also has great hopes that this material could be used for medical packaging (as well as hoping to help conserve our planet, Arora is a medicine student). Seemingly then, the product which she’s in the process of patenting, carries some distinct advantages over those other shrimp plastics created some years ago. And that’s great news – because we need plastic alternatives, and we need them now.